Brass Insert Nut

For parts with interior threads called out, heat-set threaded inserts can be added post 3D printing of plastic.

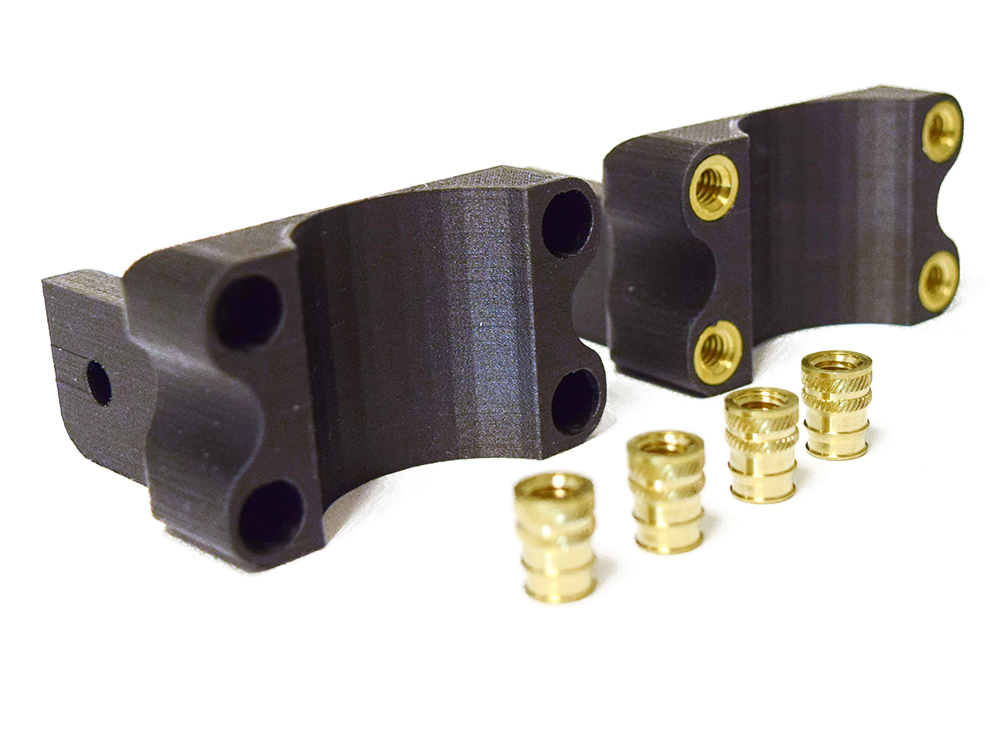

The Brass Heat Set Threaded Round Insert Nuts is used every day for assemblies and components that need to be joined together. When fasteners are used in traditional manufacturing, bolts are often tapped straight into the metal substrates. 3D printed parts are unique from a material and robustness standpoint, therefore threaded holes can wear easily if the fasteners are taken on and off multiple times. Heat-set threaded inserts are your method for success for these types of assemblies.

The Heat Set Threaded Round Insert Nut has been designed for post-mold installation into notch-sensitive thermoplastics using heat. It features very high pull-out and torque resistance.

A heat-set threaded insert has two important features. The inside of the brass piece of hardware has a nice, threaded thru the hole. The exterior has ridges, so when installed using heat, the plastic can easily flow around and then solidify. Once solidified, the insert is in place, making it resist torque and pull-out.

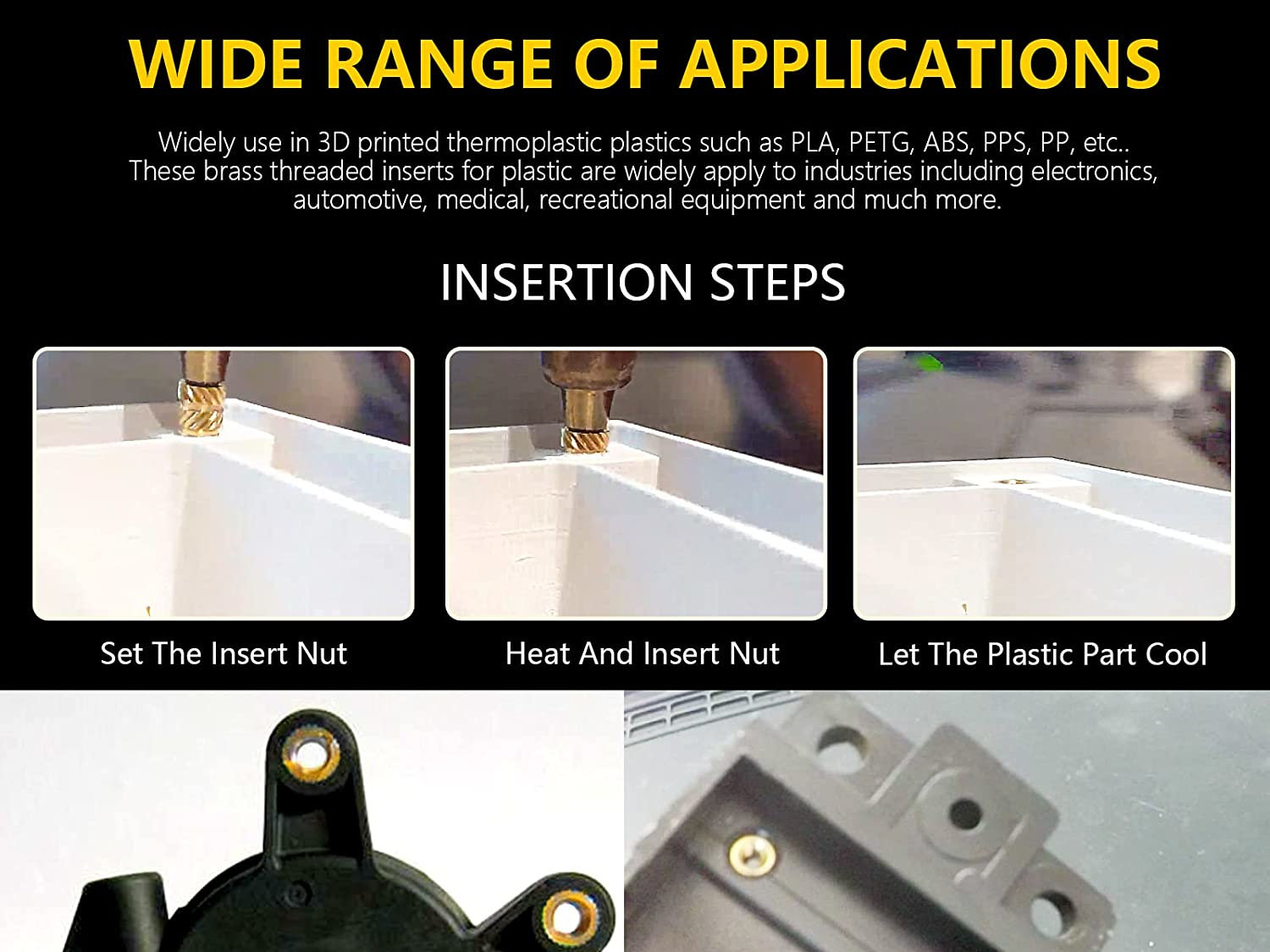

Insertion Steps:

Tool needed: a soldering iron is required during installation.

Step 1: Set the insert nut - Firstly, set the insert nut on the 3D printed plastic part surface.

Step 2: Heat and insert nut - Secondly, use the soldering iron to heat the insert. When the surrounding plastic softens, push the insert down.

Step 3: Let the plastic part cool - As the plastic cools, the plastic becomes hard again and the screw can now be tightened.